Executive Summary

The hospital’s Midwest Fetal Care Center struggled with maintaining proper room pressurization and ventilation.

The Minneapolis hospital of Children’s Minnesota faced challenges in maintaining proper room pressurization and ventilation levels, impacting the Midwest Fetal Care Center. A leading national mechanical contractor and KMC Controls, a recognized expert in HVAC control, provided a sustainable solution using the KMC Airflow Measurement System (AFMS). The collaboration resulted in immediate, positive results, including reliable measurement data for outside, return, and supply airflow rates, ensuring a balanced pressurization schema and greater confidence in environmental quality. The AFMS implementation also promises long-term benefits, including Advanced Fault Detection and Diagnostics (AFDD), virtually zero maintenance, and a test case for transitioning the hospital’s Building Automation System (BAS) to an open protocol.

Customer Profile

Children’s Minnesota is a prominent pediatric health system with a Level I Trauma Center, known for its excellence and commitment to children’s healthcare. The hospital sought a solution to address pressurization and ventilation issues.

The Challenge

The hospital’s Midwest Fetal Care Center faced persistent challenges in maintaining proper room pressurization and ventilation levels according to ASHRAE Standard 170. The commissioned Air Handling Unit (AHU) struggled due to unreliable measurements from thermal dispersion Airflow Measurement Devices (AMDs). The thermal dispersion AMDs suffered from accuracy drift over time, necessitating frequent operational modifications.

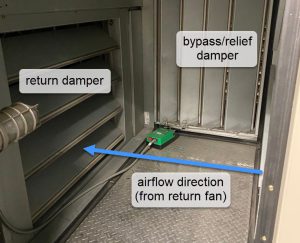

The BAS’s control schema, featuring independently operated relief and return dampers, exacerbated performance issues and complicated fan speed balancing.

The commissioned Air Handling Unit (AHU) struggled due to unreliable measurements from thermal dispersion airflow measurement devices.

Independently operated relief and return dampers exacerbated performance issues and complicated fan speed balancing.

Additionally, the unit’s duct configuration deviated from ASHRAE Standard 111 requirements for accurate measurements using traditional AMDs.

Over 100 linear feet of OA ductwork feeds the AHU.

The ductwork includes an OA booster, complicating the configuration.

The duct configuration includes sharp bends that deviate from ASHRAE Standard 111 requirements for using traditional AMDs.

This setup resulted in downtime during servicing, impacting hospital operation, and the mechanical contractor faced a burden dispatching technicians for manual adjustments.

The overarching challenge was the need for a sustainable solution that addressed both technical intricacies and operational disruptions. Children’s Minnesota sought a resolution to ensure consistent pressurization, ventilation, and system performance, paving the way for the collaboration with KMC Controls and the implementation of the KMC AFMS to meet these multifaceted challenges.

The Solution

The hospital’s challenges with room pressurization and ventilation were met with a comprehensive solution by using the KMC AFMS. The mechanical contractor initiated the collaboration, providing preliminary details, and a KMC Controls sales engineer conducted a thorough site walkthrough. This process facilitated the creation of a project takeoff and bill of materials for the subsequent installation.

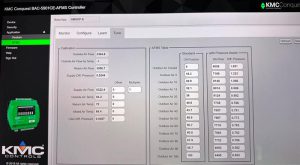

KMC Controls’ expertise guided the reuse of existing sensors and the selection and location of new sensors, ensuring an optimized solution. The AFMS inclinometer was strategically mounted on the outside air damper, while airflow measurement probes were installed on the supply and return fans. To maintain the existing BAS, data integration was achieved through BACnet/IP over Ethernet.

Upon configuration, Characterized Airflow Performance®—the measurement technology utilized by the AFMS—provided accurate readings consistent with ASHRAE Standard 111 criteria.

For the solution, the AFMS inclinometer was mounted on the OA damper. Because the dampers modulate independently, airflow probes were installed for additional pressure measurements.

Outside, return, and mixed air (pictured) temperature sensors were installed.

Airflow measurement probes were installed on the supply (pictured) and return fans.

Immediate Results

Characterized Airflow Performance® provides accurate readings consistent with ASHRAE Standard 111 criteria.

The AFMS delivers reliable measurement data for outside, return, and supply airflow rates, ensuring balanced pressurization. The hospital is now equipped with a reliable and sustainable airflow measurement solution, instilling greater confidence in the space’s environmental quality.

Furthermore, the ability to view key statistics through a wall-mounted NetSensor—such as Air Changes per Hour and AFDD troubleshooting basics—provides valuable insights.

The mechanical contractor gained practical experience in installing the KMC AFMS and balancing complex AHUs, further enhancing their capabilities and expertise.

Long-Term Benefits

Data integration with the AFMS (green) was achieved through BACnet/IP over Ethernet, offering a path toward a more open and standard protocol for the hospital.

The hospital gained a valuable tool for trend analysis over time, enabling proactive maintenance and performance metrics tracking. The embedded AFDD of the KMC AFMS provide continuous monitoring, enabling ASHRAE Guideline 36 AFDD routines. For example, the OA damper position feedback reported by the inclinometer allows for continuous monitoring of damper blade deterioration and hysteresis in damper actuator linkages.

Long-term reliability is ensured, as the KMC AFMS consistently monitors all measurements for accuracy drift. The AFMS can reestablish the performance curve on demand, reducing the unit’s downtime and minimizing the need for maintenance or recalibration. The hospital benefits from virtually zero maintenance for the life of the installation, ensuring optimal performance and efficiency over time.

In addition, this test case for migrating to BACnet/IP devices offers a path toward a more open and standard protocol for the hospital.

Conclusion

The KMC AFMS successfully addressed the hospital’s challenges, providing an efficient, cost-effective, and sustainable solution. This case study demonstrates the value of KMC Controls’ expertise in HVAC control, offering long-term benefits for healthcare facilities. Facilities managers can trust KMC Controls’ solutions to enhance HVAC performance, ensuring optimal environmental conditions for occupants. For more information about the KMC AFMS, please visit the AFMS solutions page or contact the KMC Controls sales team.

The Children’s Minnesota logo is the trademark/service mark of its owner, used with permission after approval of this content.

Cart

Cart