Installations

Children’s Minnesota – Minneapolis Hospital

Children’s Minnesota – Minneapolis Hospital

The Minneapolis hospital location of Children’s Minnesota faced challenges maintaining room pressurization and ventilation levels, impacting its fetal care unit.

- Independently operated relief and return dampers

- Nonstandard duct geometry

- Accuracy drift of thermal dispersion AMDs

Denver Public Schools

Denver Public Schools

The installation at Denver Public Schools took less than 6 man-hours. It was completed in a single day on a Daikin rooftop unit with powered exhaust.

- Supply air duct pitot array

- Trended by KMC Commander

- Monitoring outside air

- Existing factory mount Microtech controller

Chicago Public Schools

Chicago Public Schools

This installation has a large air handler unit that moves 55,000 cubic feet of air per minute. It also includes a mixing box the size of a room with several dampers for outdoor air and return air.

- Whole building air handler unit – 55K CFM

- Supply air fan inlet measurement

- Third party balancer

Reliable. Efficient. Genius.

The KMC Airflow Measurement System (AFMS) stands out as the best option for value in air flow systems. It helps achieve sustainable HVAC solutions by offering:

- The ability to monitor airflow and ensure system efficiency across a wide range of HVAC applications

- Highly accurate and repeatable measurements

- A solution enabling ASHRAE Guideline 36 sequences, allowing you to use your preferred method of measurement

- Automated field calibration for hassle-free, efficient installation

- Integrated fault detection and diagnostics for peace of mind and simplified system management

- Installation in nearly all equipment types

- Low maintenance and lower cost of ownership

Accurate, Repeatable Measurements for Optimal Performance.

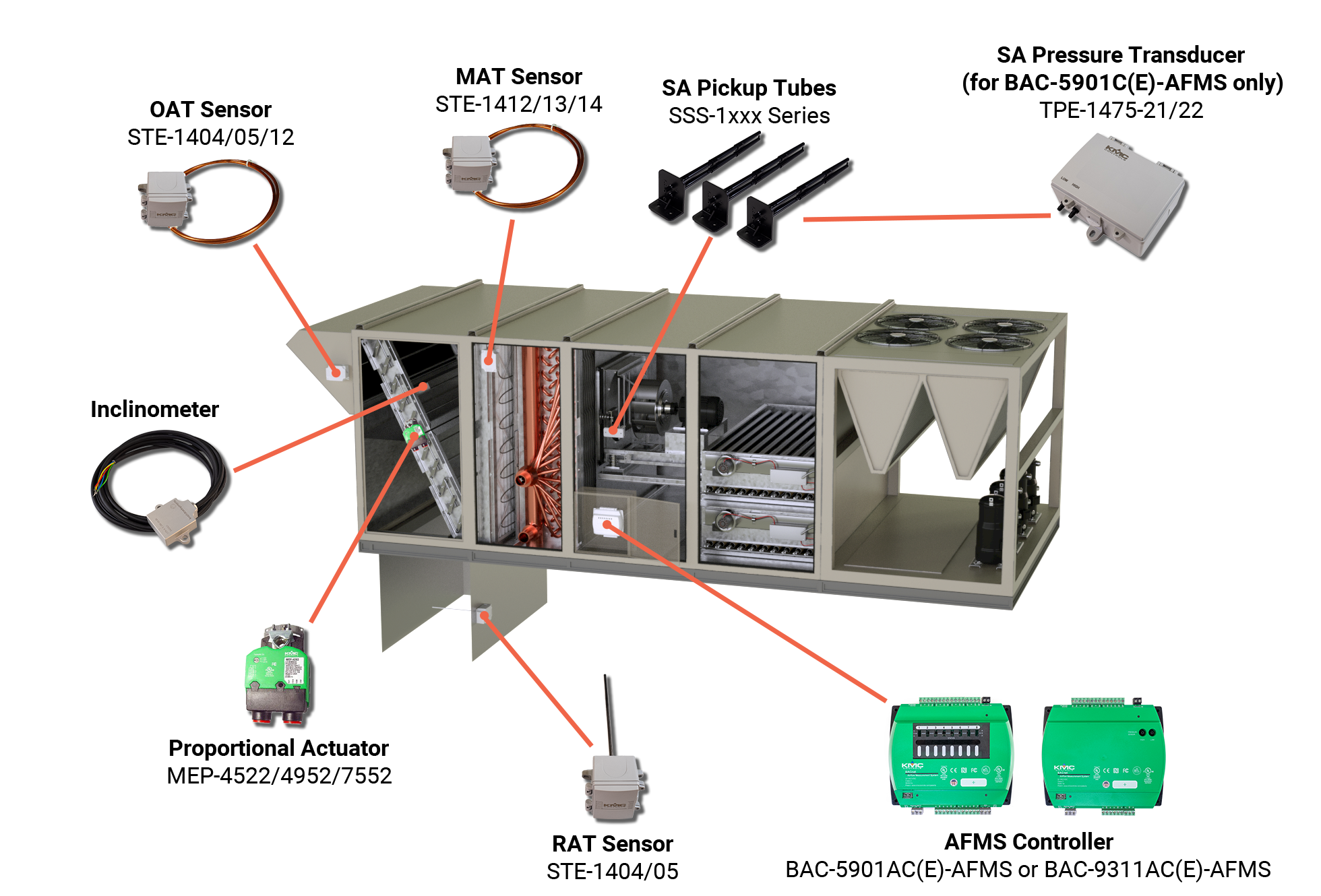

Achieve precise and consistent supply, outside, and return air flow measurements across a wide range of equipment with the KMC AFMS.

From small, packaged rooftop units to large, built-up air handlers, this innovative solution ensures reliable and efficient HVAC operation for enhanced performance and maximum energy savings.

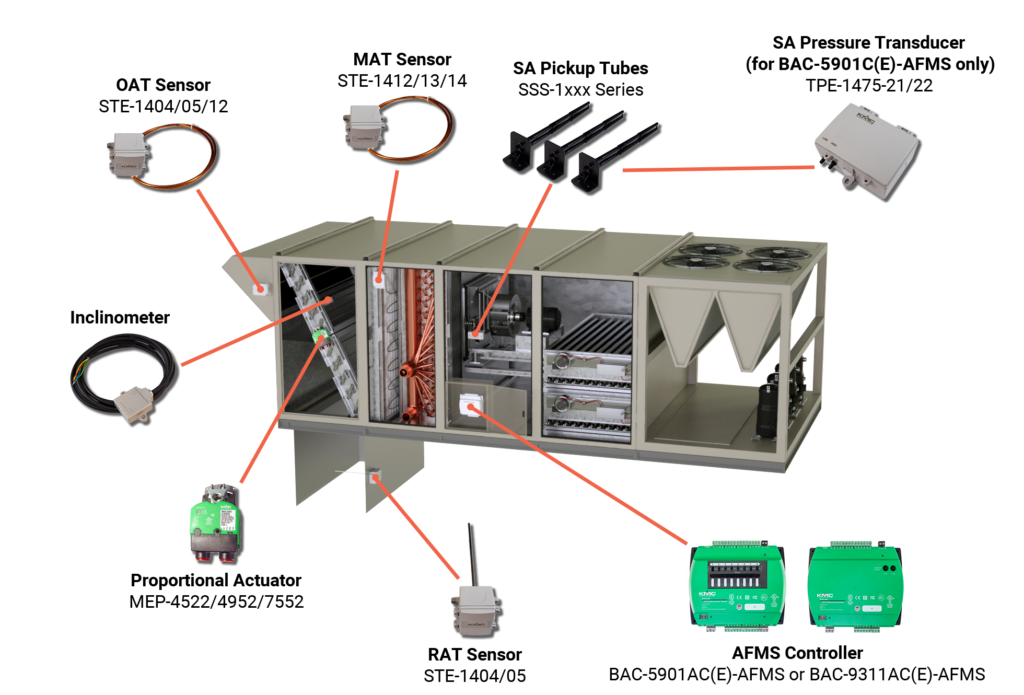

Standard Rooftop Unit (RTU) Application

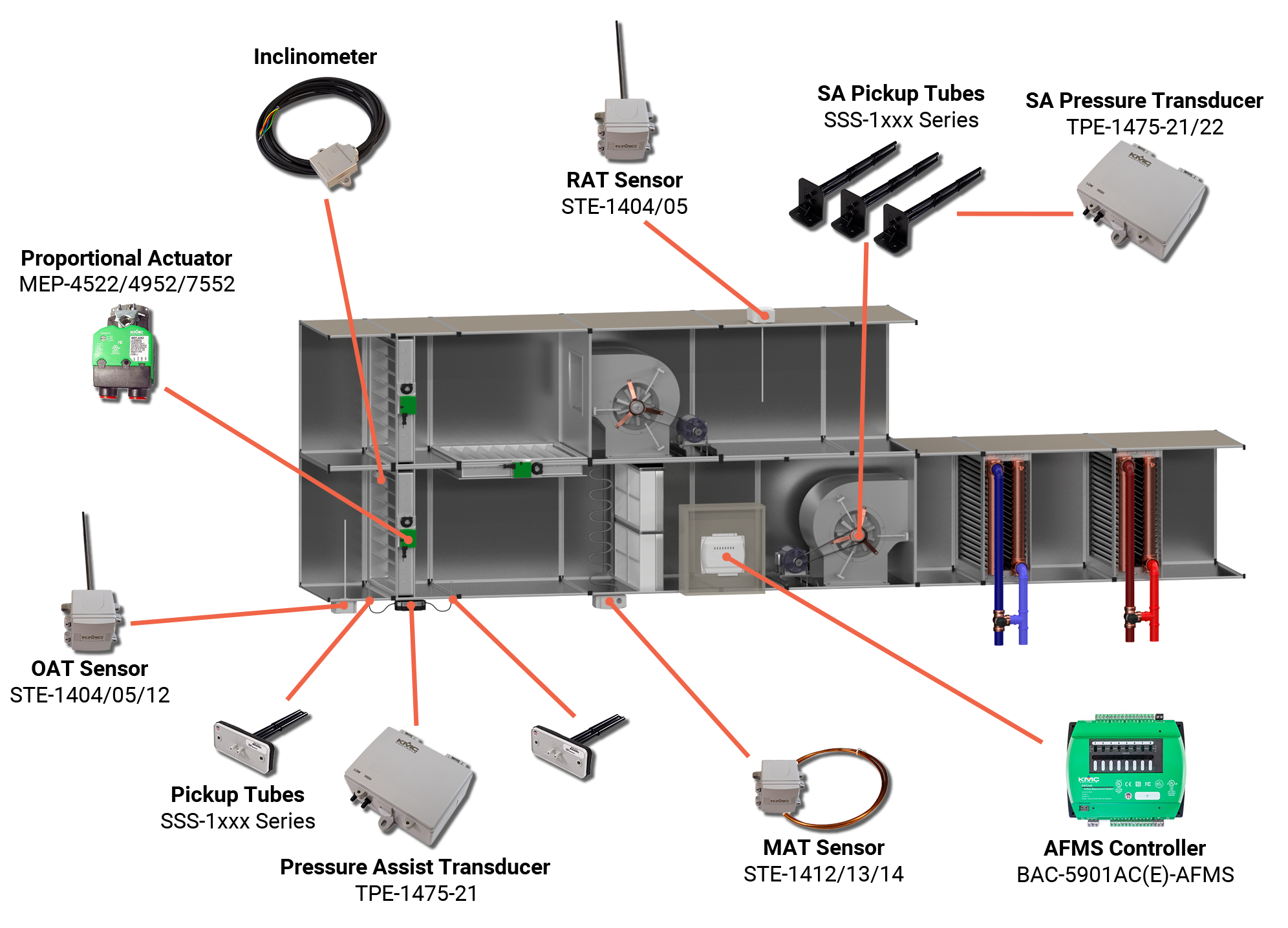

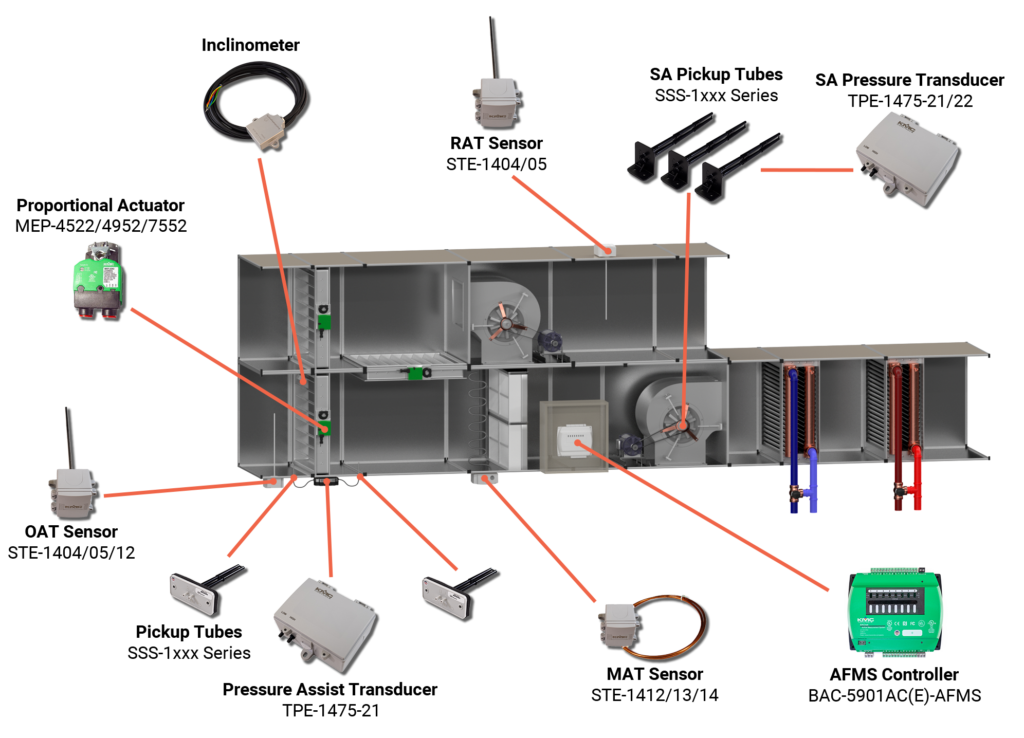

Air Handling Unit (AHU) Outside Air Damper (OAD) Pressure Assist Application

Standard Rooftop Unit (RTU) Application

Air Handling Unit (AHU) Outside Air Damper (OAD) Pressure Assist Application

Key Features

Accurate Airflow Measurement

Accurate Airflow Measurement

The KMC AFMS goes beyond the function of a standalone airflow stations. It provides accurate and repeatable measurements for outside, supply, and return airflow. Ambient weather, airborne pollutants, and bends and restrictions in mechanical air delivery systems do not impact its accuracy. Embedded performance diagnostics monitor system performance to ensure the accuracy of its readings.

Automated Commissioning

Automated Commissioning

The KMC Airflow Measurement System automatically characterizes system performance during commissioning, using the same methods as a TAB technician. After commissioning, it provides equipment control and diagnostics to monitor and report performance.

Compliance With IAQ Regulations

Compliance with IAQ Regulations

Ventilation is the first line of defense for healthy buildings. Smart infrastructure and high-performing buildings guidelines require accurate outdoor airflow measurements as a key part of efficient and healthy building operation.

Smart Building Ready

Smart Building Ready

The KMC AFMS integrates easily with IoT and building automation systems, enabling real-time data sharing and system diagnostics. This ensures optimal performance and contributes to smarter, more efficient buildings.

Built on Industry Standards

Built on Industry Standards

The KMC Airflow Measurement System (AFMS) meets ASHRAE standards and supports BACnet communication, ensuring seamless integration with building automation and IoT systems. It provides accurate airflow data and diagnostics for optimized system performance.

Expanded Equipment Compatibility

Expanded Equipment Compatibility

The KMC Airflow Measurement System can be used with a variety of mechanical systems, including:

• Unit ventilators

• Packaged rooftop

• Complex built-up air handler

• Custom equipment

Frequently Asked Questions

Occupant Health, Comfort, & Performance

Most people spend most of their time indoors, and bringing fresh outside air inside is one of the best ways to improve the air we breathe.

The EPA says Americans spend about 90% of their time indoors, where pollutants can be two to five times higher than outdoors. Combustion byproducts, allergens, mold, pesticides, lead, asbestos, ozone, and volatile organic compounds can release pollutants, many of which people find inside buildings.

Is your building getting enough outside air? If not, occupants might complain of headaches, fatigue, or irritation. These are common signs of building-related illness (BRI) or sick building syndrome (SBS).

Poor air quality costs the U.S. $150 billion each year, with $93 billion of that from lost productivity due to symptoms of SBS. And with the impact of COVID-19, the costs of poor ventilation are rising.

Fresh air is vital for health. ASHRAE, CDC, EPA, WHO, and others all agree that ventilation is important for better indoor air quality. Researchers have demonstrated that proper ventilation boosts productivity and cognitive function by 8-11% by improving indoor air quality (IAQ).

Compliance with Standards

ASHRAE standards (62.1, 111, and 189.1) recommend a minimum ventilation rate of 15 CFM per person in residential buildings to ensure good indoor air quality (IAQ) and reduce health risks. Experts consider ventilation, or the exchange of indoor air with fresh, conditioned outside air, the first line of defense for healthy buildings.

ASHRAE Standard 170 outlines the required number of air changes per hour (ACH) based on the type of space.

In addition, smart infrastructure and high-performing buildings guidelines stress that accurately measuring outdoor airflow is essential for building design and achieving certifications like WELL® or RESET®.

Optimize Energy Efficiency

Ventilation is critical to occupant wellness and performance. Measuring outdoor airflow accurately can improve the experience of building occupants and significantly increase energy efficiency.

After the energy crisis in the 1970s, national conservation efforts reduced ventilation to just five cubic feet of air per minute (CFM) per person—a 66% decrease from previous standards. To further reduce energy use, building designers started sealing windows and doors to minimize the entry of untreated outside air.

Economizers became common in many HVAC systems, recirculating treated air to lower energy consumption. However, these systems are typically controlled by standalone devices that use enthalpy measurements, which have led to even further reductions in ventilation.

Demand Control Ventilation (DCV) and fresh air reset systems aim to adjust airflow based on the number of occupants, often using indoor CO2 levels as a way to measure occupancy and regulate ventilation.

Social Trends

Fresh air has always been important, but it has often been overlooked. To save costs, monitoring and controlling indoor air quality has typically been one of the first things to be cut.

The COVID pandemic has highlighted the need for confidence in the safety of indoor spaces, making it a key factor for many occupants when deciding to return to the office.

Among the critical factors that Facility Managers and Building Owners must consider are:

Direct link between improving IAQ and occupant performance (all sectors)

Confusion around best practices to improve IAQ

Workforce reluctance to reoccupy buildings

Tenants moving to buildings that prioritize building wellness

Consumer desire for user-friendly interface showing healthy building attributes

IAQ certification standards

Current Market Deficiencies

Traditional technology has inherent performance limitations. A brief list of common occurrences that can impact traditional outdoor airflow measurement device accuracy include:

- Wind gusts

- Low air velocities

- Ambient weather variations (temperature and humidity)

- Airborne particulate matter (dust, dirt, pollen, waste)

- Damper blade deterioration and system hysteresis

- Mechanical system bends or restrictions (that affect airflow)

Other common concerns include:

- Physical equipment limitations

- Unrepeatable, inconsistent measurements

- Prohibitive cost of implementation and maintenance

Traditional Technologies

Many airflow measurement technologies exist, but few provide accurate, repeatable results for all types of equipment. Most devices have strict installation requirements, limiting where they can be used.

- Differential pressure (using a pitot tube) is a standard method for measuring airflow, but it’s not suitable for duct systems with bends or low velocities.

- Thermal dispersion sensors are good for low-velocity airflow but can be affected by pollutants like dust, dirt, and animal waste. They also don’t perform well with bends or restrictions in the ductwork and require regular maintenance and recalibration.

- Conditioned orifice plates are effective but can be costly and require system modifications. They also struggle to accurately measure low velocities because they need to increase differential pressure, which reduces accuracy.

Cost

The cost to install the KMC Airflow Measurement System is often much lower than traditional technologies. Many existing systems require expensive modifications to ductwork or equipment to meet factory standards for accurate measurements.

To achieve a good return on investment, an airflow measurement solution must be affordable and reliable. The KMC AFMS uses inclinometer technology and a characterized system method, providing an economical way to improve performance. Real-time measurements, KPIs, and diagnostics can be displayed locally or integrated into a building automation system.

Ongoing maintenance costs are low because supply airflow measurements are taken in filtered air. Additionally, existing sensors and actuators can be reused for calibration, lowering installation costs. A hard-wired sensor connection is recommended for better reliability.

System diagnostics are performed regularly using automated methods (ASHRAE standards 62.1, 111, and 189.1). If needed, the system can be recalibrated to maintain long-term accuracy.

Recently, ESSER funding has been made available by the federal government to improve Indoor Air Quality (IAQ) in educational facilities. The amount of funding and qualifying activities vary by state. The amount of funding and qualifying activities vary by state and are listed in the State Plan. For details, consult your state’s Department of Education website. ESSER funds have been used for installing airflow measurement stations and improving ventilation, including products like KMC CommanderAQ.

Using a characterized damper airflow measurement system makes proper ventilation achievable in nearly any building.

What’s the solution?

The patent pending KMC Airflow Measurement System is a revolutionary approach to measuring outside airflow. The system uses a characterized system method to measure outside, return, and supply airflow.

A high-precision inclinometer monitors the outside air damper blade position, ensuring performance is unaffected by weather, wind gusts, low air velocities, pollutants, turbulent airflow, or duct bends and restrictions—issues that commonly impact traditional airflow measurement technologies.

How it works

The KMC Airflow Measurement System measures airflow by characterizing outside air damper performance, similar to how a pump performance curve is created.

This method helps the system determine the composition of supply air at any damper position.

The system creates the characterization curve automatically using a Learn Mode sequence. It uses an inclinometer mounted on the damper actuator blade and the Temperature Ratio Equation. As an alternative, a qualified TAB technician can manually create the curve.

During Learn Mode, the damper is moved to several known positions. At each position, airflow and temperatures (outside, return, and mixed air) are allowed to stabilize before being sampled, averaged, and stored in the curve.

Learn Mode Characterization

ASHRAE standard 111 requires 25⁰-50⁰F temperature difference (∆T) between Return Air (RA) and Outside Air (OA) temperature for the most accurate calculations.

The KMC AFMS Learn Mode can automatically start when there is a temperature difference greater than 15°F between OA and RA for at least two hours.

This includes time for temperature sensor stabilization and multi-sampling.

The requirements for initiating Learn Mode are minimal.

Execute when:

- Building can maintain >15⁰ ∆T between RA and OA for minimum 2 hours

- Typically at night (less thermal variance due to Sun & reduced occupancy / less need for system override)

- There is no possibility of mechanical or environmental faults

- E.g. Freezing, over-pressurization, excessive humidity, etc.

Damper Characterization Method

The outside air damper characterization curve is the foundation for all measurements on the KMC AFMS.

A high-precision inclinometer (compliant with AHRAR Standard 189.1) is attached to the damper blade to measure its position with accuracy up to 0.001°. This helps reduce errors caused by damper blade wear or linkage issues that can’t be detected through actuator feedback.

The characterization curve defines the composition of supply fan airflow using the Temperature Ratio Equation in ASHRAE Standard 111, similar to how a TAB technician balances the equipment.

Characterizing damper performance also ensures accuracy, regardless of intake configuration, non-laminar airflow, or leaks in the mechanical system.

Pressure Assist

Many equipment manufacturers include features like filters or air bypass streams in mixed air chambers. As the equipment operates, these components can affect outside airflow being drawn into the equipment.

To monitor these conditions, the KMC AFMS uses a Pressure Assist feature. This feature can be used on any system but is specifically recommended when:

-

- Relief fan that is variable speed OR operating independent of mixed air damper position

- Return fan that is NOT controlled by a Supply / Return Fan offset

- Bypass damper for a heat recovery system

- Return VAV boxes

- Supply to return bypass (or bypass damper is used in place of a VFD)

Pressure Assist corrected airflow rates are determined by the OA damper characterization process and aggregation of variables affecting airflow through the mixed air chamber

Control Modes

If the KMC AFMS controller is being used to manage equipment operation, it may be configured for four basic modes:

- Pass Through

- Damper is controlled by an external source (existing BAS, etc.)

- Mixed Air Temperature

- OA Volume

- Air changes / hour

- Damper Position

NOTE: Customized control modes / equipment sequences can be accomplished through additional programming

Diagnostics and Faults

The KMC AFMS natively monitors the following properties, to ensure accuracy and equipment performance:

- Sensor Faults

- Outside Air, Mixed Air, Return Air, Differential Pressure

- Damper Faults

- OA Flow Status

- Active Control Mode Faults

- Position, Mixed Air, OA Volume

- Title 24 Faults

These diagnostics may be viewed locally or reported through a building management system.

Let's Get Started.

Thank you for your interest in the KMC Airflow Measurement System (AFMS). Fill out the form below, and we’ll provide you with tailored information to help you make the best decision for your building’s airflow needs. Whether you're looking for a solution to improve energy efficiency, indoor air quality, or system performance, we’re here to assist you every step of the way. Your next step towards a smarter, more efficient building starts here.

Cart

Cart