Click to see full size images

By Jason D. Mills, Director of Marketing and Communications

KMC Controls, a leading provider of building automation solutions, partnered with Comfort Controls, one of their system integrators in Texas, on a new green energy project to install an offshore windmill farm.

Previously dominated by Allen Bradley PLC for decades, Comfort Controls has used KMC’s solutions to take over the offshore industry by storm. This includes the successful installation of KMC products on Shell Olympus, Shell Appomattox, Shell’s largest floating platform offshore, as well as on Vito, Whale, Auger, Ursa, Chevron Bigfoot, Tahiti, Ballymore, and many other offshore oil rigs. Comfort Controls won all of these jobs due to their craftsmanship and KMC Controls’ product durability, as well as Comfort Controls’ expertise in offshore service.

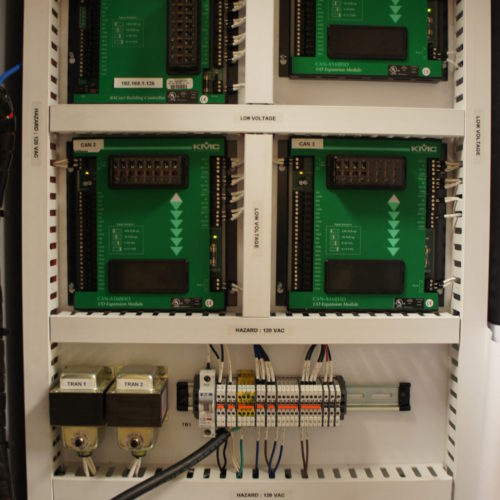

The durability and flexibility of KMC’s products were crucial on the South Fork Offshore Substation Project, where the unique challenges of an offshore environment required solutions that could withstand harsh conditions and provide reliable performance. KMC’s solutions were able to meet these requirements, allowing Comfort Controls to successfully complete the project.

The wind farm will be positioned on the outer continental shelf of US federal waters, specifically within a Bureau of Ocean Energy Management (BOEM) renewable energy lease located southeast of Block Island, Rhode Island, and east of Montauk Point, New York.

Offshore wind farms can provide a clean and renewable source of energy, helping to reduce reliance on fossil fuels and combat climate change. In addition, offshore wind farms can help to diversify energy sources and provide a reliable source of energy for the region. Offshore wind farms can also create jobs and economic opportunities in the area.

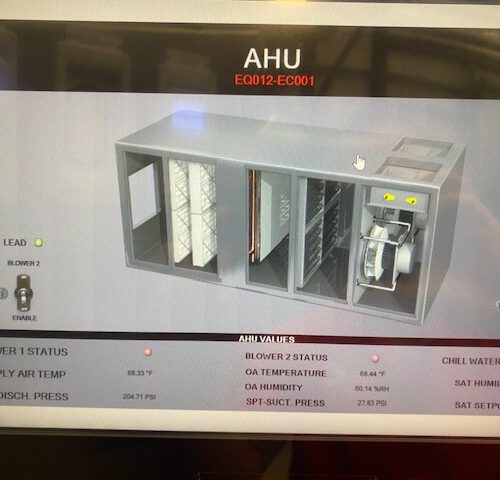

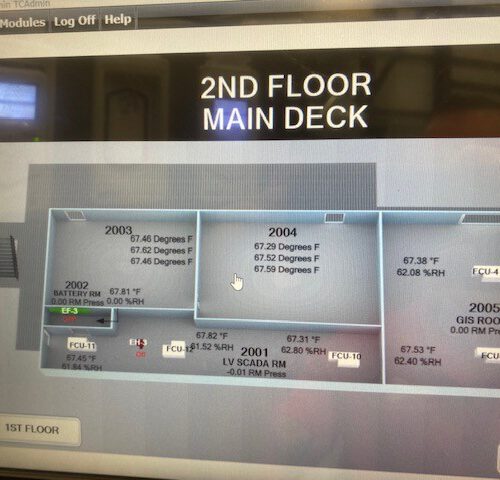

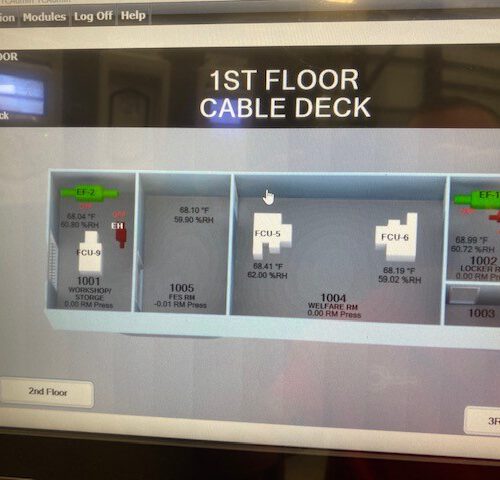

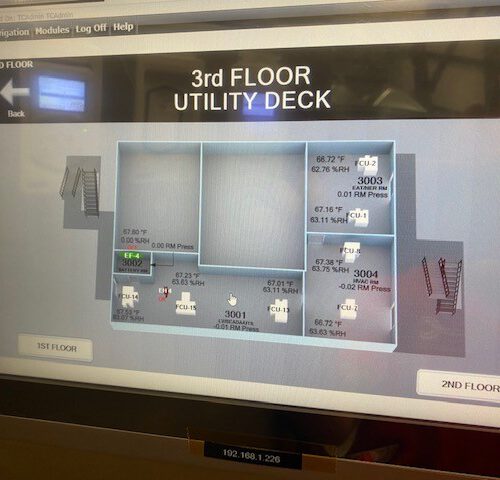

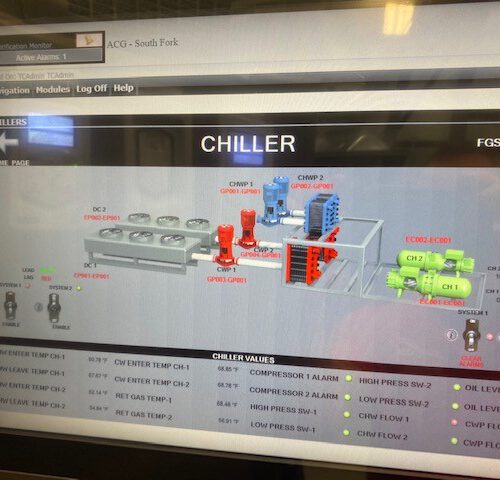

The project presented unique challenges, as the offshore environment is harsh and difficult to control. Comfort Controls was able to overcome these challenges by utilizing the solutions provided by KMC Controls, both in hardware and software. Southfork, being an unmanned platform required a reliable HVAC control to maintain the required space temperature, humidity, building pressure, even monitor and alarm if a water leak in the chill water loop is detected. The HVAC is 100% redundant insuring that these conditions are always operating per design even if one system fails.

“KMC was able to handle the environment, the heavy industrial environment, very well, and their Controllers’ flexibility in programming, backward compatibility, and made in the USA stamp has been a big plus for us as well,” said Jeremy Sisson, General Manager at Comfort Controls.

One of the main challenges that Comfort Controls faced on the South Fork project was the need to maintain acceptable indoor conditions for all equipment and areas. This was particularly important for the high voltage (HV) and medium voltage (MV) gas insulated switchgear (GIS) rooms, which will be equipped with KMC Controls’ building management system for control and monitoring purposes. HV and MV GIS rooms are specialized areas that contain equipment used to control and switch electrical power at high and medium voltage levels.

This project is “part of the going green initiative and this is only the first one,” Sisson said. There will be several more after this we hope to be a part of using the KMC product. We’re excited to be a part of this green initiative and are confident in KMC’s ability to deliver reliable and effective solutions for this project and the seven others that are already in contract.”

Another challenge that Comfort Controls needed to overcome was the need to prevent the ingress of salt, substances, and humidity into enclosed areas with critical equipment. This was addressed by utilizing KMC Controls’ filtering systems, which were able to reduce the salt-in-air content to a safe level.

The project also required the ability to recover overpressure within a short amount of time after door opening and closing. KMC Controls’ HVAC system was able to meet this requirement, ensuring that the pressurized rooms remained safe and functional.

Comfort Controls’ knows the importance of having reliable and flexible solutions for their clients. When it comes to building automation, KMC Controls has consistently provided the products that have allowed Comfort Controls to successfully complete their projects.

The success of multiple offshore and industrial projects has created the opportunity for new projects like South Fork. The ability of KMC’s products to provide solutions in a variety of industries and environments has been a major factor in Comfort Controls’ continued success. The success of these projects further showcases the capabilities of KMC’s products and their ability to provide solutions in a variety of industries and environments.

In addition to their durability and flexibility, the cost-effective nature of KMC’s solutions has also played a key role in Comfort Controls’ success. The competitive pricing of KMC’s products allows Comfort Controls to provide their clients with high-quality building automation systems without breaking the budget.

As the building automation industry continues to evolve, Comfort Controls will continue to rely on KMC Controls’ solutions to provide their clients with the reliable and cost-effective solutions they need. The durability, flexibility, and competitive pricing of KMC’s products make them a valuable partner for Comfort Controls and their clients.

“We’re excited to continue partnering with KMC on future projects and are confident in their ability to deliver effective solutions,” Sisson concluded.

If you would like to become a KMC Controls system integrator, or if you’d like to learn more about any of the solutions from the Building Geniuses at KMC Controls, email us at info@kmccontrols.com.

Cart

Cart