While aiming to achieve the goals mentioned above, building systems play a critical role in industrial settings. First, “basic” environmental conditions, such as consistent temperature and humidity, can become critical to manufacturing operations when sensitive equipment, product quality standards, environmental safety, or health compliance requirements are involved. In such cases, the building system becomes integral to meeting manufacturing objectives.

Beyond these basic environmental controls, a comprehensive industrial control management solution can optimize and automate more complex functions. A variety of equipment, such as pumps, cooling towers, drying ovens, and refrigeration units, can be monitored and managed from a single platform.

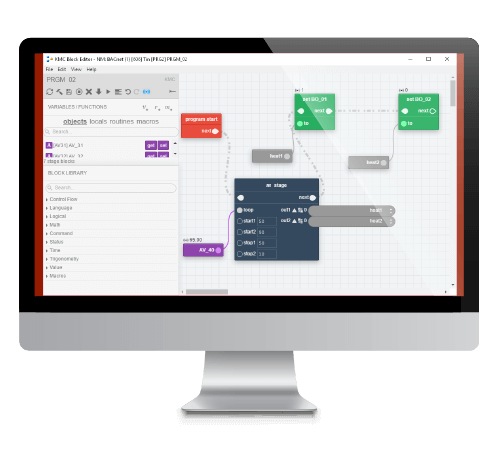

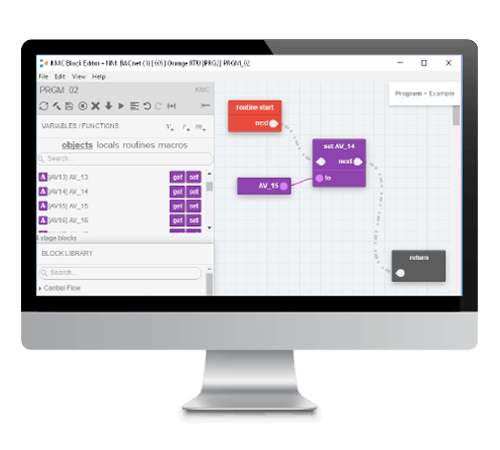

In fact, the potential for such integrations is nearly unlimited with a knowledgeable facility automation contractor and the right mix of hardware and software. Furthermore, as manufacturing facilities grow and operational needs change, a system’s backwards compatibility and capacity to network across buildings and campuses becomes increasingly important. A sophisticated industrial control solution takes all these factors into account, delivering reliable hardware and flexible software to ensure dependable operation, centralized control, and maximum convenience. KMC carries a full line of building automation hardware and software to meet these demands.

Implementing Industrial Internet of Things (IIoT)

The Industrial Internet of Things (IIoT) is the ultimate tool for leveraging these potential integrations. The Internet of Things is an invisible network of anything connected to the Internet, including devices and physical hardware, that communicate with one another to send and receive data. The Industrial IIoT, then, is the integration of these devices and hardware across an industrial facility’s building and operations. The term covers many industries, applications and use cases, so its only limits are those of the imagination.

Building controls are a low-risk, high-yield IoT opportunity in industrial settings. Typically, building controls are already in place within a given facility, and many may already be capturing the data needed to integrate an Industrial IoT solution. Technology like KMC Commander can aid IoT implementation across a host of commercial-grade building systems, sensors, and meters. KMC Commander assimilates the data needed to make informed decisions and presents them in an easy-to-read interface on any computer or smart device. It can also automate decisions to free up human resources. And the best part is, this Industrial IoT solution is scalable; start by solving just one pain point like humidity or temperature control, then build out a full Industrial IoT strategy as time and budget allows. The flexibility of the platform allows for a virtually infinite number of integrations over time.

KMC Controls also offers a suite of products with a legacy of helping to manage industrial building controls, even if IoT isn’t yet an option. Explore them here, then find a KMC Partner to get started on your project.

Cart

Cart